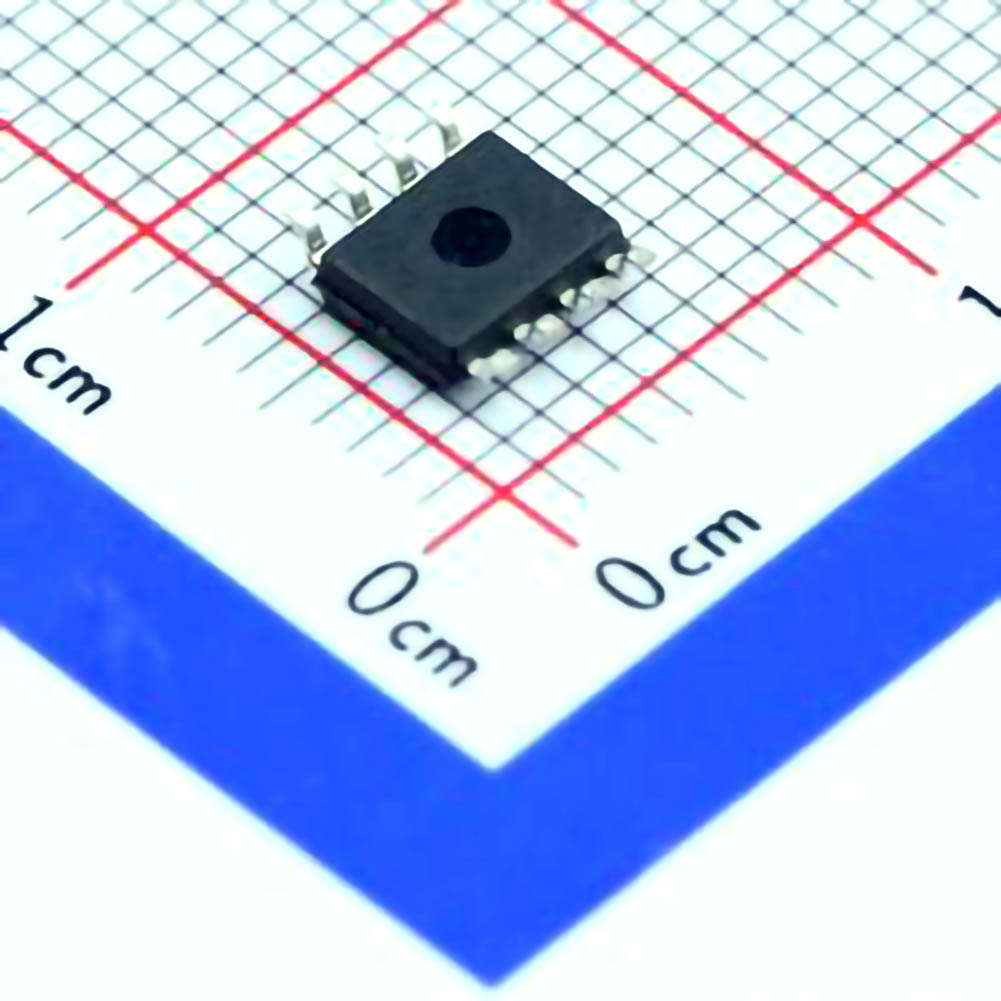

24LC256T-I/SN Common troubleshooting and solutions

The 24LC256T-I/SN EEPROM is a popular choice for many embedded applications due to its reliability and versatility. However, like any electronic component, it can present challenges during use. This article explores common issues users might encounter with the 24LC256T-I/SN and provides practical solutions for troubleshooting these problems, ensuring a smoother development experience.

24LC256T-I/SN, EEPROM troubleshooting, embedded systems, I2C Communication , Memory issues, data integrity, EEPROM solutions

Common Issues with 24LC256T-I/SN EEPROM and How to Fix Them

The 24LC256T-I/SN is a highly reliable I2C-based EEPROM ( Electrical ly Erasable Programmable Read-Only Memory) that offers 256Kb of memory, making it an excellent choice for a wide range of applications, from microcontroller interfacing to data storage in embedded systems. However, like any electronic component, issues may arise during the design, implementation, or use of the 24LC256T-I/SN. Let’s explore the most common problems users might face with this component and how to resolve them.

1. I2C Communication Failures

One of the most frequent problems when working with the 24LC256T-I/SN EEPROM is I2C communication failure. If the microcontroller cannot communicate with the EEPROM, several factors could be at play:

Solution:

Check Wiring Connections: Ensure the SDA (data line) and SCL (clock line) are correctly connected between the EEPROM and the microcontroller. The I2C bus requires pull-up resistors on both lines. Typically, 4.7kΩ pull-up resistors are used, but this can depend on the bus capacitance and the communication speed.

Check Power Supply: Ensure the EEPROM is receiving the correct power (typically 2.5V to 5.5V, depending on your configuration). If the EEPROM isn’t powered correctly, communication won’t be possible.

Verify Addressing: The 24LC256T-I/SN requires the correct 7-bit I2C address. Verify that the EEPROM's address is set correctly in the software. The chip’s address is determined by the state of the A0, A1, and A2 pins. Ensure these pins are configured properly for the intended address.

2. Incorrect Read/Write Operations

If the EEPROM is not performing read or write operations correctly, it could be due to several issues such as Timing problems or improper addressing. Some of the most common causes of incorrect data retrieval or storage include:

Solution:

Check Timing: The EEPROM requires certain timing constraints to function correctly. For example, after a write operation, the EEPROM needs a certain amount of time to complete the write cycle (tWR). Failing to wait for the write cycle to complete before initiating another read/write operation can cause errors.

Data Integrity: When performing write operations, ensure that data is being correctly written to the intended memory location. Verify that the address pointer is being correctly updated before each read or write operation to avoid overwriting data or reading incorrect data.

Use of Write Enable: The 24LC256T-I/SN EEPROM requires a Write Enable command before a write operation. If this is missed, the EEPROM will not accept the data, leading to write failures.

3. Bus Contention

In systems with multiple I2C devices, bus contention can occur if more than one device tries to control the I2C bus at the same time. This can lead to corrupted data or communication failure between the EEPROM and the master device.

Solution:

Check for Multiple Masters: Ensure that only one device is acting as the I2C master. The I2C protocol is designed for one master and multiple slave devices, so bus contention can occur if multiple devices are trying to control the bus.

Verify Unique Addresses: Ensure that every device on the I2C bus has a unique address. The 24LC256T-I/SN EEPROM supports address pins (A0, A1, A2), which allow you to configure different devices on the same bus. Ensure that these pins are set correctly to avoid address conflicts.

4. Corrupted or Lost Data

Sometimes, data corruption or loss may occur during the storage or retrieval of data from the EEPROM. This can be frustrating, especially in embedded systems where data integrity is crucial.

Solution:

Check Power Stability: In some cases, data loss can occur if the EEPROM loses power while writing data. This can happen due to an unstable power supply or sudden power interruptions. Use a stable power source and, if possible, a capacitor to filter power noise.

Ensure Proper Write Cycle Completion: As mentioned earlier, the 24LC256T-I/SN requires time to complete the write operation. Ensure that the master controller waits for the write cycle to complete (typically a few milliseconds) before initiating another operation.

Write Protect Pin: If the WP (Write Protect) pin is low, the EEPROM is in a write-protected state and will not accept any write operations. Ensure that this pin is not unintentionally held low during normal operations.

Advanced Troubleshooting Tips and Solutions for 24LC256T-I/SN EEPROM

5. High Power Consumption

In some cases, users may find that their 24LC256T-I/SN EEPROM is consuming more power than expected, especially in low-power applications where efficiency is crucial.

Solution:

Check Sleep Mode: The 24LC256T-I/SN has a low-power sleep mode when not in active use. Ensure that the device is transitioning correctly between active and sleep modes. If the device remains in active mode unnecessarily, power consumption will increase.

Optimize I2C Frequency: Higher I2C clock frequencies can increase power consumption due to faster switching of the data and clock lines. If power efficiency is a priority, reduce the I2C clock speed to lower the power usage.

Use External Capacitors : If your application is sensitive to power fluctuations, consider using external decoupling capacitors to stabilize the power supply and minimize noise that could cause excessive power draw.

6. Overwriting Memory Locations

Another issue often encountered with EEPROMs like the 24LC256T-I/SN is the accidental overwriting of memory locations, which can happen when the memory addressing is not handled carefully.

Solution:

Implement Memory Management : Ensure that memory addressing is carefully managed to avoid overwriting critical data. Many applications store configuration settings or system parameters in specific memory locations, and overwriting these could result in system failure. Implement robust memory management algorithms to protect important data.

Check for Boundary Errors: When reading or writing data, ensure that the address pointer does not exceed the EEPROM's memory size (256Kb). Attempting to write outside the valid memory range can lead to corrupted data or failure of operations.

7. Electrical Noise or Interference

EEPROMs like the 24LC256T-I/SN are often used in environments with electrical noise or interference, especially in industrial applications. Noise can disrupt I2C communication, leading to data corruption or communication failures.

Solution:

Use Proper Grounding and Shielding: Ensure that the EEPROM’s I2C lines are properly shielded and that there is a solid ground connection to reduce the effect of electrical noise. For longer I2C communication distances, using twisted pair cables or additional shielding can help reduce noise.

Use I2C Buffers or Repeaters : In cases of long I2C bus runs or high noise environments, consider using I2C buffers or repeaters. These devices can help maintain signal integrity, especially when the bus length exceeds typical limitations.

8. Unstable Readings or Failed Writes after Extended Use

If the EEPROM appears to function correctly initially but starts showing erratic behavior after some time, it could be due to wear or improper handling during write operations.

Solution:

Check for Endurance Limits: The 24LC256T-I/SN EEPROM has a limited number of write cycles (approximately 1 million write cycles per byte). While this is quite high for most applications, continuous writing to the same location over extended periods could eventually cause degradation. Ensure that your application is designed to minimize frequent writes to the same memory locations.

Wear Leveling: If frequent writes are required, consider implementing wear leveling techniques where data is written to different locations to spread out the wear and extend the EEPROM's lifespan.

Conclusion

The 24LC256T-I/SN EEPROM is a powerful and versatile memory component, but like any technology, it can present challenges during implementation and use. By understanding the common issues outlined in this article and applying the troubleshooting tips and solutions, you can ensure reliable performance and data integrity in your embedded systems. Whether you're dealing with I2C communication failures, data corruption, or power consumption problems, these solutions will help you get the most out of your EEPROM and maintain a smooth development process.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.