BMP390 Barometric Sensor Accuracy Drops: Solutions for Optimal Performance

Understanding the BMP390 Barometric Sensor Accuracy Drops

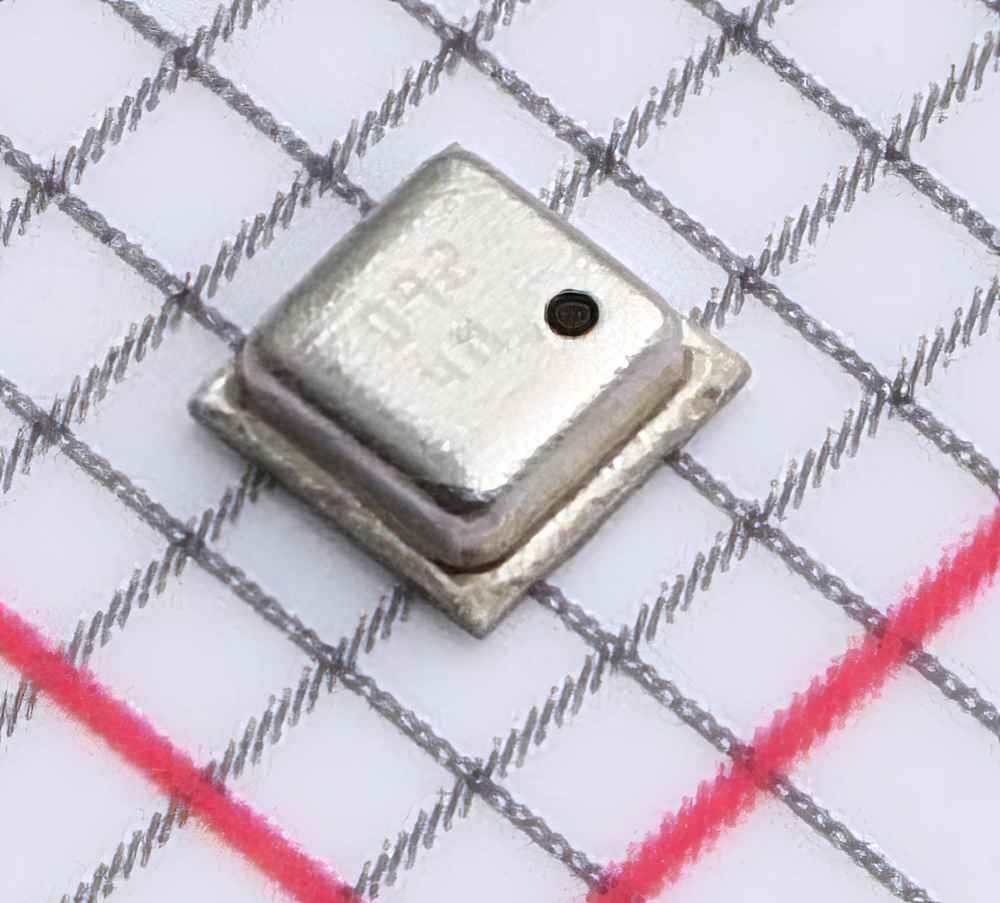

The BMP390 barometric sensor is a crucial component in a variety of applications, from altitude measurement to weather prediction and even in indoor navigation systems. Known for its small size, high precision, and Power efficiency, the BMP390 offers reliable barometric pressure readings. However, like any electronic device, its performance can degrade over time or due to certain environmental factors. One of the most common issues faced by users is a noticeable drop in accuracy.

This article delves into the causes of BMP390 sensor accuracy drops and explores solutions to ensure optimal performance.

Factors That Affect BMP390 Accuracy

Temperature Fluctuations:

One of the primary factors that influence the accuracy of the BMP390 is temperature. The BMP390 is designed to operate within a specific temperature range. If the surrounding environment experiences sudden temperature changes or falls outside the sensor's recommended operating range, its readings can become unreliable. In extreme cold or heat, the sensor’s internal components may become less stable, affecting pressure readings and leading to inaccurate data.

Altitude Changes:

The BMP390’s core functionality revolves around measuring barometric pressure to estimate altitude. Rapid altitude changes, such as those occurring in environments with sudden air pressure shifts, can temporarily impact sensor readings. This is especially common in high-mountainous areas or in aircrafts, where atmospheric pressure changes drastically. A sudden drop or rise in air pressure may cause the BMP390 sensor to give false readings until it recalibrates to the new environmental conditions.

Electrical Noise and Interference:

Electrical noise and interference from nearby electronic components can also contribute to sensor accuracy issues. The BMP390, like many other Sensors , is sensitive to electromagnetic interference ( EMI ) and can be affected by devices such as motors, transmitters, and other equipment that emit electromagnetic fields. These interferences can distort the sensor’s ability to detect accurate barometric pressure, especially in environments with dense electronic activity.

Improper Calibration:

Calibration is a crucial process for any sensor, and if it’s not performed correctly or frequently, the BMP390’s accuracy will degrade. Sensors often come pre-calibrated from the manufacturer, but over time, environmental conditions, usage patterns, or even aging of the sensor can cause a drift in readings. Failure to recalibrate periodically can lead to significant discrepancies in the data collected, particularly in professional-grade applications like weather forecasting or geophysical research.

Humidity and Condensation:

Humidity and condensation within the sensor housing can lead to incorrect readings. Excess moisture can disrupt the functioning of the internal electronics or even cause corrosion over time. In outdoor applications or in humid environments, condensation can form within the sensor housing, affecting the internal components and leading to inaccurate readings.

Power Supply Variations:

The BMP390 requires a stable and clean power supply to function optimally. Voltage fluctuations or power supply instability can cause performance drops. Power supply issues may affect the accuracy of the pressure sensing elements, as well as the signal processing components, leading to erroneous pressure data.

Aging of the Sensor:

Like most electronic components, the BMP390 sensor may experience some degradation in performance as it ages. Although these sensors are designed for long-term reliability, over several years, small deviations can occur in the sensor’s internal circuitry, affecting its accuracy. The degradation process can be slow but cumulative, ultimately impacting the precision of pressure readings.

The Impact of Accuracy Drops

Accuracy drops in the BMP390 sensor can have varying levels of impact depending on the application. In some use cases, such as basic weather applications or casual outdoor activities, minor inaccuracies might not significantly affect overall performance. However, for applications requiring high precision, such as altitude measurement in aviation or high-precision weather monitoring, these drops in accuracy can lead to flawed data, compromising both safety and decision-making.

In scientific studies or critical systems, relying on inaccurate barometric data can lead to flawed analysis, poor predictions, and even potential system failures. For example, in altitude tracking for drones or aircraft, small errors in barometric pressure readings can lead to incorrect altitude readings, which can compromise navigation and safety.

Solutions for Optimal BMP390 Sensor Performance

While it’s natural for sensor performance to degrade slightly over time, there are a number of practical steps that users can take to maintain or restore the BMP390’s accuracy. The following solutions outline how to tackle the common issues that cause the BMP390 sensor’s performance to drop.

1. Regular Calibration

Calibrating your BMP390 barometric sensor at regular intervals is one of the best ways to ensure its accuracy. This process resets the sensor’s internal reference point, ensuring that pressure readings are accurate and consistent. Calibration should be performed at least once every few months, or more frequently if the sensor is used in environments that experience significant changes in pressure or temperature.

Calibration involves comparing the sensor’s output with a known reference, such as a trusted barometric pressure reading. Many systems allow for automatic recalibration based on external references, like GPS altitude data or nearby weather stations.

For users who work with highly sensitive applications, calibration can also be performed after significant environmental changes, such as during drastic weather shifts or altitude changes, to maintain optimal accuracy.

2. Addressing Environmental Factors

Mitigating the impact of environmental factors on the BMP390 is essential to maintaining accuracy. Temperature fluctuations can be managed by insulating the sensor housing or placing it in a temperature-stabilized environment. For example, placing the sensor inside a protective casing with thermal insulation will help prevent rapid temperature changes from affecting the sensor’s performance.

In areas with high humidity, moisture-resistant enclosures can help protect the sensor from condensation and prevent internal components from becoming damaged. These enclosures will ensure that the sensor remains dry and able to function optimally.

For altitude-related accuracy issues, it is important to ensure that the sensor has adequate time to adapt to sudden environmental pressure changes. If the sensor is used in a high-variation pressure environment, such as in aircraft, periodic recalibration and advanced pressure compensation algorithms should be used to ensure accuracy during rapid altitude shifts.

3. Use Proper Shielding Against Interference

To minimize the impact of electromagnetic interference (EMI), it’s critical to place the BMP390 in locations where it is less likely to come into contact with other sources of electronic noise. Shielding the sensor using materials such as metal enclosures or conductive shielding fabrics can block EMI, ensuring that the sensor receives accurate pressure readings without distortion.

In some cases, you may also use low-pass filters to clean up any noise in the sensor’s data output. These filters will help to reduce any erratic or noisy data caused by interference.

4. Stable Power Supply

To ensure accurate readings, the BMP390 requires a clean and stable power supply. Using a high-quality, regulated power source will help prevent voltage fluctuations that could lead to inaccurate sensor data. Additionally, implementing low-dropout regulators (LDOs) or decoupling capacitor s can smooth out any sudden power spikes or dips, which could otherwise impact sensor performance.

When deploying the BMP390 in battery-powered applications, consider using a power management system that adjusts the supply voltage to stay within the sensor's optimal operating range.

5. Monitor Long-Term Wear and Tear

Over time, components can degrade due to prolonged use. Keeping track of the sensor's performance and conducting periodic checks to ensure that the readings align with expectations can help identify any gradual performance losses. If you notice any signs of sensor degradation, such as inconsistent readings or failure to respond to environmental changes, it may be time to replace or recalibrate the sensor.

Replacing the sensor periodically can prevent long-term accuracy degradation, ensuring that the BMP390 consistently delivers reliable and precise data.

Conclusion

The BMP390 barometric sensor is a valuable tool in a wide range of applications, from environmental monitoring to altitude tracking. However, its performance can be compromised by factors such as temperature fluctuations, humidity, power supply issues, and external interference. By understanding these potential causes and implementing the solutions outlined above, users can maintain the sensor's accuracy over time, ensuring optimal performance and reliable data.

By calibrating regularly, addressing environmental challenges, using proper shielding, ensuring a stable power supply, and monitoring long-term wear, the BMP390 can continue to deliver accurate pressure readings for a variety of applications, contributing to better decision-making and operational efficiency.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.