BTA16-600BRG Reliable Application Design in Industrial-Grade AC Switching

Introduction to BTA16-600BRG and its Role in Industrial AC Switching

In the fast-evolving world of industrial applications, precision, reliability, and efficiency are paramount. Whether in manufacturing, automation, or energy Management , industries require components that can handle high voltages and currents, ensuring long-term performance under demanding conditions. One such component that stands out in the realm of AC switching is the BTA16-600BRG.

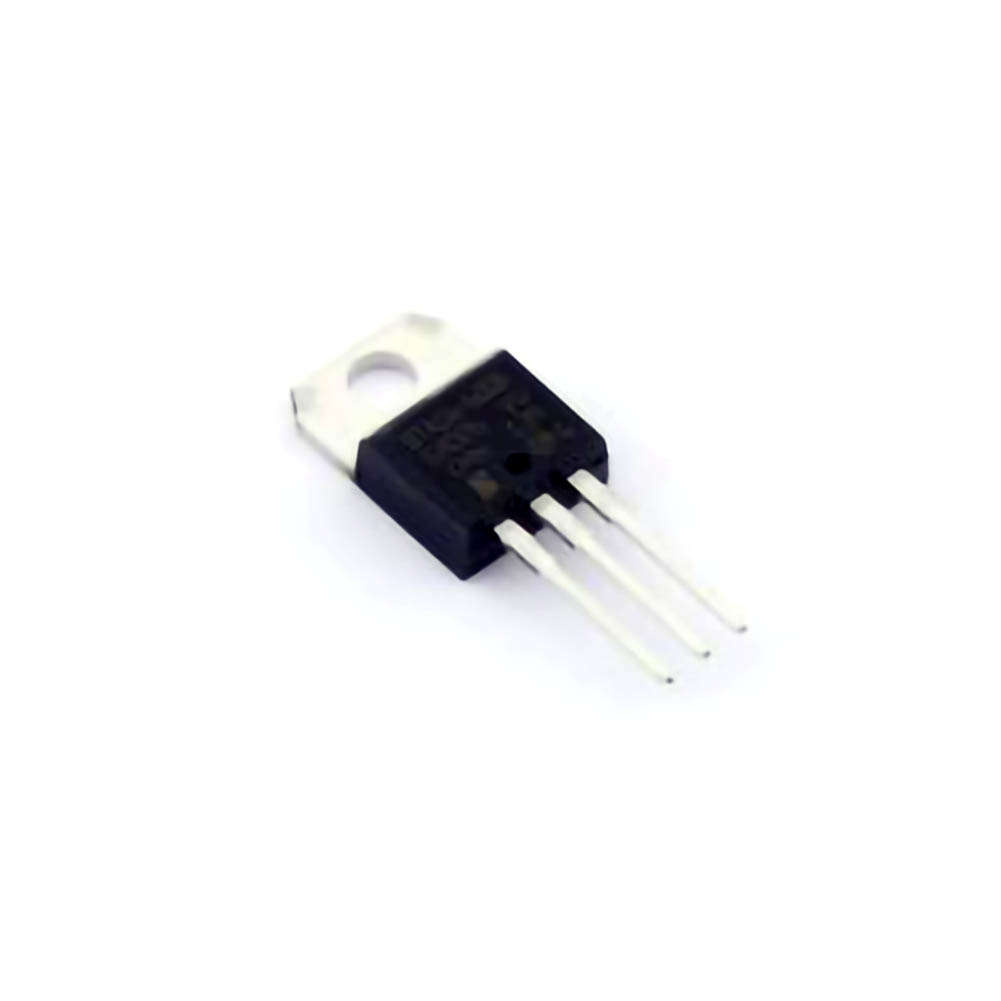

The BTA16-600BRG is a silicon-controlled rectifier (SCR) designed specifically for industrial-grade AC switching applications. This robust and reliable thyristor plays a pivotal role in Power control systems, offering high-performance features that make it ideal for a wide range of industrial environments. This article explores its design characteristics, advantages, and practical applications to help engineers make informed decisions about incorporating it into their systems.

Understanding the BTA16-600BRG

At its core, the BTA16-600BRG is a three-terminal device capable of controlling the flow of alternating current (AC) by acting as a switch. The component is designed to handle peak reverse voltages of up to 600V, making it well-suited for high-voltage industrial systems. The BTA16-600BRG is part of the BTA series from STMicroelectronics, known for its versatility and high-power handling capabilities.

This SCR operates by allowing current to flow through it when triggered and blocking the current when it is not. The device is typically used in applications where high voltage and current need to be switched on and off rapidly, such as in motor controls, light dimmers, and heating systems. It features excellent thermal stability and robustness, even in harsh operating environments.

Key Features and Benefits

The BTA16-600BRG is designed to offer several key advantages that make it a standout choice for industrial-grade AC switching:

High Current Handling: With a maximum RMS on-state current of 16A, the BTA16-600BRG can efficiently handle significant electrical loads without degradation in performance.

High Voltage Rating: Its ability to withstand up to 600V reverse voltage makes it suitable for use in high-voltage AC systems, common in industrial and power control applications.

Low Power Loss: Thanks to its efficient design, the BTA16-600BRG minimizes power loss during operation, which is crucial for reducing energy consumption and enhancing system efficiency.

Compact Design: Despite its impressive performance specifications, the component is compact, allowing for easy integration into space-constrained industrial control panels or systems.

Thermal Stability: The device is designed to withstand temperature fluctuations, ensuring stable operation even in extreme conditions.

Long Lifespan: Due to its solid-state design and high-quality construction, the BTA16-600BRG has a long service life, which reduces maintenance costs and system downtime.

Industrial Applications of the BTA16-600BRG

The versatility of the BTA16-600BRG makes it an invaluable component in a variety of industrial applications. Some common uses include:

Motor Control: In industrial machinery, controlling the speed and operation of motors is critical. The BTA16-600BRG can be used in motor speed control circuits, providing smooth and reliable switching.

Heater Control: Many industrial heating systems require precise temperature control. The BTA16-600BRG can regulate power to heating elements, ensuring consistent performance.

Lighting Control: The component is also widely used in dimmer circuits for industrial lighting systems, allowing for smooth adjustment of light intensity.

Power Switching: Its role in power switching circuits, such as in power supplies and inverters, is crucial in managing the flow of electricity and preventing overloads.

By incorporating the BTA16-600BRG into these applications, industries can benefit from reduced energy consumption, improved system reliability, and enhanced operational efficiency.

Design Considerations and Best Practices for Using BTA16-600BRG in AC Switching

Incorporating the BTA16-600BRG into industrial-grade AC switching systems requires careful consideration of various factors to ensure optimal performance and longevity. Proper design, selection of complementary components, and understanding the device's limitations are critical for achieving the best results.

Key Design Considerations

Triggering and Control Circuit:

The BTA16-600BRG is a gate-triggered device, which means it requires an external gate signal to turn on. The triggering circuit must be designed to provide the correct voltage and current to the gate terminal. A low-power pulse is typically used to trigger the thyristor. Proper design of the gate drive circuit ensures that the BTA16-600BRG turns on reliably, with minimal power consumption and no voltage spikes.

Heat Management:

One of the primary design considerations when working with high-power components like the BTA16-600BRG is thermal management. The device can generate heat during operation, and without adequate cooling, its performance could degrade, or the component could fail prematurely. Heat sinks or other thermal dissipation techniques must be employed to maintain the device's temperature within safe operating limits. Ensuring that the heat is effectively dissipated is key to the longevity and efficiency of the system.

Snubber Circuits:

In AC switching applications, inductive loads can generate voltage spikes when switching occurs. These spikes can damage sensitive components. To prevent this, snubber circuits are often used in conjunction with SCRs like the BTA16-600BRG. A snubber typically consists of a resistor and capacitor placed in series with the thyristor to absorb the transient energy and prevent voltage surges that could lead to failure.

Application-Specific Load Considerations:

Different industrial applications will have varying types of loads that require specific attention. For example, in motor control applications, the load is often inductive, requiring particular attention to the turn-on and turn-off behavior of the SCR. The BTA16-600BRG should be selected based on the specific characteristics of the load, such as its current profile and switching frequency.

Overcurrent and Overvoltage Protection:

While the BTA16-600BRG is designed to handle substantial voltage and current, protection circuitry should still be incorporated to safeguard against accidental overloads or voltage surges. Using fuses, circuit breakers, or surge protection devices in the design can help protect both the SCR and the entire system from damage due to abnormal conditions.

Mounting and Packaging:

The BTA16-600BRG is available in a range of packages, including through-hole and surface-mount options. Selecting the appropriate package type depends on the application’s space constraints, cooling requirements, and ease of assembly. For higher power applications, a through-hole package with a larger thermal dissipation area might be more suitable, while for compact systems, surface-mount versions are preferable.

Best Practices for Reliability and Efficiency

To ensure the BTA16-600BRG operates efficiently and reliably in industrial systems, following these best practices is essential:

Regular System Maintenance: Regular inspection and maintenance of AC switching systems, including components like the BTA16-600BRG, can help detect issues early and prevent failure. Monitoring parameters such as current, voltage, and temperature can provide valuable insights into system health.

Design for Redundancy: In critical applications where system uptime is crucial, designing for redundancy (such as using multiple SCRs or backup systems) can ensure that failure of one component does not lead to a total system failure.

Surge Protection: Ensuring that proper surge protection measures are in place is essential for extending the lifespan of the BTA16-600BRG. Transient voltage spikes are common in industrial environments and can lead to irreversible damage if not properly managed.

Component Matching: Ensure that all components in the circuit, including the BTA16-600BRG, are well-matched in terms of ratings and specifications. Using a component that exceeds the required ratings may result in unnecessary costs, while undersized components could lead to failure under heavy load.

Conclusion

The BTA16-600BRG is a powerful, reliable solution for industrial-grade AC switching applications. Its ability to handle high voltages and currents, combined with features like thermal stability, long lifespan, and low power loss, makes it an ideal choice for various industrial systems. However, to fully leverage its potential, engineers must consider the proper design and integration of complementary components, such as triggering circuits and heat management solutions.

By following best practices and ensuring a well-designed, efficient system, industries can harness the power of the BTA16-600BRG to achieve superior performance, energy efficiency, and long-term reliability. Whether for motor control, heater regulation, or lighting systems, the BTA16-600BRG stands as a cornerstone in the world of industrial-grade AC switching.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.