OPA192IDBVR Common troubleshooting and solutions

Understanding the OPA192IDBVR Operational Amplifier and Common Issues

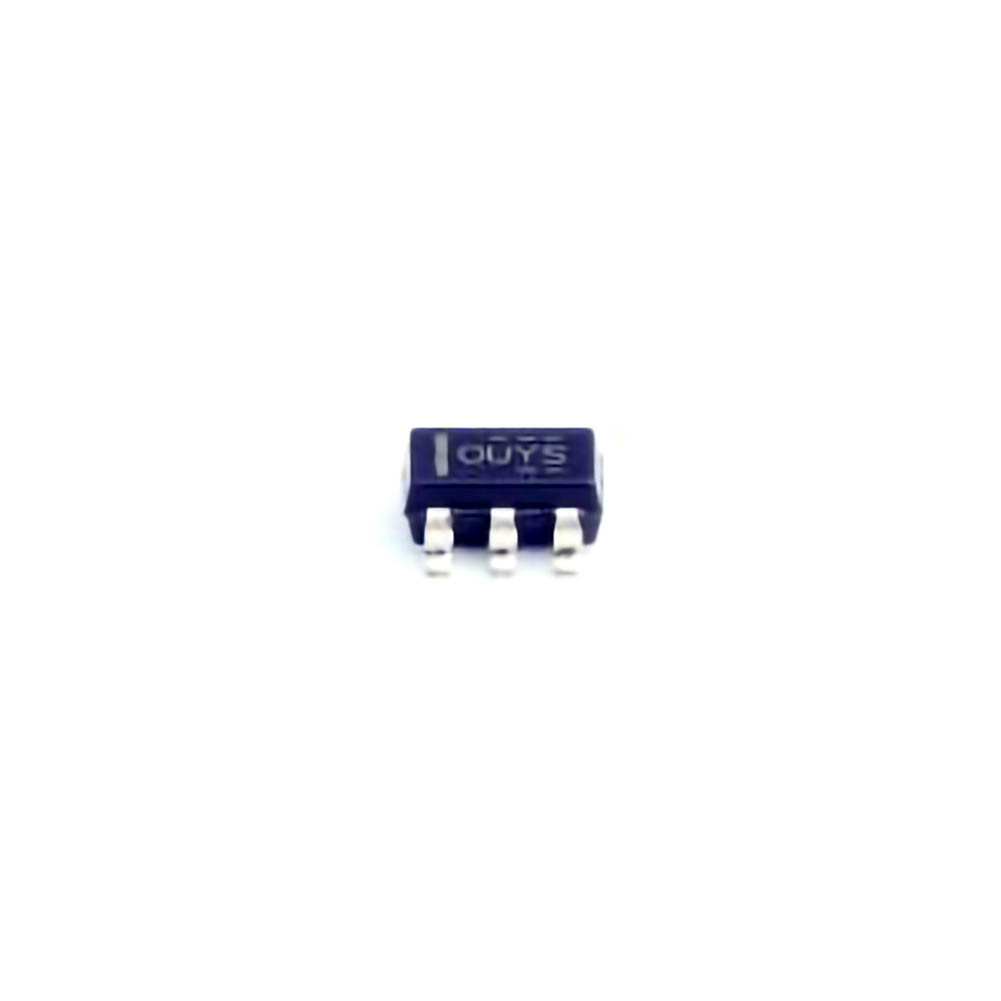

The OPA192IDBVR is a high-precision operational amplifier (op-amp) manufactured by Texas Instruments. Designed for low-offset and low-noise applications, the OPA192IDBVR finds its use in a wide array of electronic systems, from precision signal processing and medical equipment to Audio systems and industrial sensors. Despite its remarkable performance and versatility, like any electronic component, it may occasionally exhibit issues that can disrupt functionality or performance. In this part of the article, we will explore the typical applications of the OPA192IDBVR and identify some common problems that users might face when working with this op-amp.

Typical Applications of the OPA192IDBVR

Before diving into the troubleshooting process, it’s essential to understand the role of the OPA192IDBVR in various circuits. This op-amp is known for its ultra-low offset voltage, low noise, and rail-to-rail output, making it ideal for a range of precision applications, including:

Precision Analog Signal Conditioning: The OPA192IDBVR is frequently used in circuits that require high-accuracy voltage sensing and signal amplification, such as in temperature sensors, strain gauges, and pressure transducers.

Audio and Audio Signal Processing: With its high performance in low-noise environments, the OPA192IDBVR is ideal for audio preamplifiers and audio processing systems.

Medical Instruments: Because of its low offset and high accuracy, the OPA192IDBVR is widely used in medical devices that demand precise measurements, such as ECGs and blood pressure monitoring devices.

Test and Measurement Equipment: The operational amplifier is crucial in test equipment, where high precision is necessary for signal amplification and measurement.

Common Issues with OPA192IDBVR

While the OPA192IDBVR is a robust and reliable op-amp, certain challenges can arise during its integration or use. The following are common issues that users might encounter:

Excessive Offset Voltage

Despite the OPA192IDBVR’s low offset voltage specifications (less than 25 μV typically), in some circuits, you may still encounter a situation where the offset voltage is much higher than expected. This can result in inaccurate signal measurements or distorted output signals.

Saturation or Clipping of Output

If the output signal from the OPA192IDBVR is saturated or clipped, it indicates that the amplifier is unable to operate within its normal linear region. This could be caused by improper Power supply voltage levels or incorrect input signal conditions.

Unstable Operation

Stability is crucial in many high-precision applications. If the OPA192IDBVR exhibits oscillation or instability, it could be due to external components, such as capacitive loading, or improper feedback network design.

Noise and Humming

The OPA192IDBVR is designed to be low-noise, but users may experience excessive noise or humming in their circuits, especially in sensitive applications such as audio processing or instrumentation. This can result from poor PCB layout, power supply noise, or grounding issues.

Overheating or Power Consumption Problems

The OPA192IDBVR, like all operational amplifiers, generates some heat during operation. If the op-amp gets too hot, it can cause performance degradation or even failure. Improper voltage supply or incorrect component choices in the circuit can contribute to excessive power consumption or thermal issues.

Initial Troubleshooting Steps

When encountering problems with the OPA192IDBVR, the first step is to systematically diagnose the issue. Here are some initial troubleshooting steps to take:

Check the Power Supply: Ensure that the OPA192IDBVR is powered within its recommended operating voltage range (±2.25V to ±18V). Over-voltage or under-voltage conditions can lead to improper operation or damage.

Verify the Input Signals: Ensure that the input signals are within the specified range for the op-amp. An input voltage that is too high or too low can drive the op-amp into saturation or clipping.

Review the Circuit Design: Make sure that the external components, such as resistors, capacitor s, and feedback loops, are correctly chosen and connected. Incorrect component values or configurations can lead to oscillations, instability, or performance degradation.

Inspect PCB Layout: Poor PCB design can lead to various issues, such as parasitic capacitance, noise, and grounding problems. Verify the layout to minimize these effects.

Practical Solutions for OPA192IDBVR Operational Amplifier Issues

Having identified the most common issues that can occur with the OPA192IDBVR operational amplifier, the next step is to explore practical solutions for resolving these problems. Each issue can often be traced back to specific circuit or component-level problems, and addressing them with targeted solutions can restore the amplifier’s functionality and reliability.

Solution 1: Resolving Excessive Offset Voltage

Problem: Excessive offset voltage can result in inaccurate or distorted measurements, especially in precision applications.

Solution:

Use External Offset Trimming: The OPA192IDBVR provides an offset nulling feature through external resistors. By adding a trim circuit with a potentiometer, you can adjust the offset voltage to meet the required accuracy level.

Use a Different Biasing Network: In some cases, adjusting the biasing network or using low-offset, low-noise resistors in the input stage may help reduce offset voltage further.

Check Temperature Effects: The offset voltage of the OPA192IDBVR can drift with temperature changes. Use temperature-compensating techniques, such as thermally stable resistors or thermal Management , to minimize offset drift.

Solution 2: Fixing Output Saturation or Clipping

Problem: Saturation or clipping occurs when the op-amp output exceeds the voltage rails, making the signal inaccurate or distorted.

Solution:

Ensure Adequate Power Supply: Ensure that the op-amp is powered by a voltage supply that is at least 1V above the maximum expected output swing. If using a single-supply configuration, ensure the voltage is high enough to allow the op-amp to operate within its linear output range.

Limit Input Signal Amplitude: Prevent the input signal from exceeding the input voltage range specified for the op-amp. Large input signals can drive the amplifier into saturation.

Consider Negative Feedback: Proper feedback network design is essential for preventing saturation and ensuring linear operation. Adjust the feedback resistor values or introduce a buffer stage if necessary.

Solution 3: Addressing Stability and Oscillation

Problem: Instability or oscillations can occur in high-precision applications, leading to unwanted noise or erratic behavior.

Solution:

Add Compensation Capacitors : If oscillations occur, try adding small capacitors (typically in the range of 10pF to 100pF) between the output and feedback pin, or across the op-amp’s input to stabilize the gain.

Minimize Capacitive Loading: Ensure that the op-amp is not loaded with excessive capacitance, especially on the output. High capacitive loads can lead to oscillations. You may need to buffer the output or adjust the feedback network to mitigate this issue.

Check for Ground Loops: Grounding issues can cause oscillations in high-precision circuits. Ensure that the PCB ground plane is solid and continuous to avoid creating ground loops.

Solution 4: Minimizing Noise and Humming

Problem: Excessive noise or humming is especially problematic in sensitive applications like audio signal processing.

Solution:

Improve PCB Grounding: A poor ground plane or improper grounding connections can introduce noise. Use a star grounding technique and ensure that the op-amp’s ground pin has a solid, low-impedance connection to the system ground.

Use Decoupling Capacitors: Place decoupling capacitors (0.1µF to 10µF) close to the power supply pins of the op-amp to filter out high-frequency noise from the supply voltage.

Shield Sensitive Sections: For audio applications or other low-noise environments, consider shielding the op-amp circuit or placing it in a Faraday cage to reduce electromagnetic interference.

Solution 5: Solving Overheating and Power Consumption Issues

Problem: Overheating or excessive power consumption can occur if the op-amp is not properly integrated into the system.

Solution:

Check for Excessive Current Draw: The OPA192IDBVR draws very little current, but if the power supply voltage is too high or the op-amp is overdriven, it may draw excessive current. Verify that the supply voltage is within the recommended range and that no overcurrent conditions exist.

Improve Thermal Management : If the op-amp is operating in a high-power or high-temperature environment, consider adding heat sinks or improving the ventilation around the component to dissipate heat.

By carefully analyzing the root cause of any issues with the OPA192IDBVR and applying the appropriate solutions, users can ensure that this versatile operational amplifier performs optimally in their applications. With the right troubleshooting techniques and solutions, the OPA192IDBVR can continue to be a reliable component in a variety of high-precision circuits.

If you’re looking for models of commonly used electronic components or more information about OPA192IDBVR datasheets, compile all your procurement and CAD information in one place.

(Partnering with an electronic component supplier) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. (Contact us) for free today