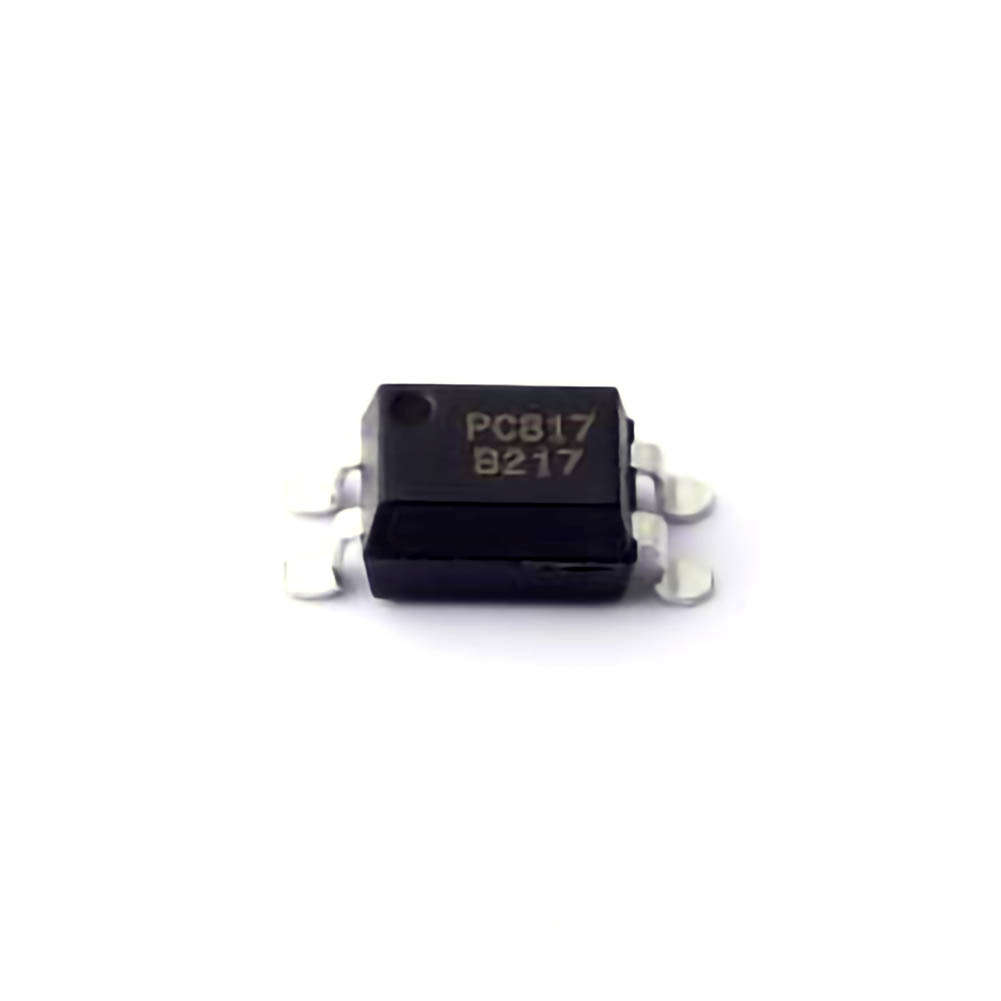

PC817 Common troubleshooting and solutions

The PC817 Optocoupler is a widely used electronic component that isolates signals between different sections of a circuit. However, like any component, it may face certain issues during its operation. This article explores common troubleshooting methods for the PC817 , as well as practical solutions to maintain optimal performance in various electronic applications.

Understanding the PC817 and Common Issues

The PC817 optocoupler is a versatile component used primarily for signal isolation in electronic circuits. It consists of an LED (Light EMI tting Diode ) and a photo transistor , which are electrically isolated but optically coup LED . This allows signals to be transferred between different parts of a circuit while maintaining electrical isolation, preventing interference, and protecting sensitive components. However, despite its reliability, issues may arise during its operation. Understanding the root causes of these problems and knowing how to troubleshoot them effectively is crucial for maintaining circuit performance.

1. PC817 Pinout and Circuit Configuration

Before diving into troubleshooting, it’s important to understand the PC817’s pinout. The PC817 has four pins:

Pin 1 (Anode of LED)

Pin 2 (Cathode of LED)

Pin 3 (Collector of Phototransistor)

Pin 4 (Emitter of Phototransistor)

Correct wiring is crucial for the proper operation of the PC817. Incorrect connections can lead to malfunction, so always refer to the datasheet to ensure the pins are properly connected.

2. Common PC817 Problems

Here are the most common issues you might encounter with the PC817:

a) Optocoupler Not Responding

One of the most common problems with the PC817 is that it doesn’t respond to input signals. This can be caused by several factors, including:

Faulty LED: If the internal LED fails, the phototransistor will never receive any signal, resulting in a non-functional optocoupler. The LED can burn out due to overcurrent, overheating, or incorrect operating voltage.

Incorrect Circuit Design: Improper voltage levels or a lack of current limiting resistors can damage the LED, causing the PC817 to malfunction.

b) Weak Output Signal

Sometimes, even though the PC817 seems to be functioning, the output signal might be weak or not strong enough to drive the next stage of the circuit. This issue can occur for the following reasons:

Inadequate Biasing: The PC817’s phototransistor needs proper biasing to function effectively. Without the correct voltage and current levels, the phototransistor may not amplify the signal properly.

Load Impedance Issues: If the load connected to the PC817’s output is too high in impedance, it can lead to weak output signals.

c) Short Circuit or Open Circuit

A short circuit or open circuit condition in the PC817 may occur if it is subjected to excess voltage or current. These conditions can permanently damage the internal components, leading to complete failure of the optocoupler. The failure can be difficult to diagnose without proper testing equipment like a multimeter or an oscilloscope.

d) Noise and Signal Interference

Optocouplers, including the PC817, are designed to isolate circuits, but they are not immune to noise. In high-frequency applications or noisy environments, the PC817 can become susceptible to signal interference. This can result in erratic behavior, signal distortion, or even complete failure of the optocoupler.

Troubleshooting and Solutions for the PC817

Once you’ve identified the issue with the PC817, the next step is troubleshooting. There are several methods you can use to diagnose and fix the common problems associated with this component.

1. Testing the PC817 Optocoupler

Before proceeding with any repairs, it’s important to confirm whether the PC817 is indeed the source of the problem. You can test the PC817 using a multimeter:

Test the LED: To test the LED portion of the PC817, use the diode testing mode of a multimeter. Place the probes on pins 1 and 2 (the anode and cathode of the LED) and check if the multimeter shows a forward voltage drop. If the LED is damaged, the multimeter won’t show any reading, and you will need to replace the optocoupler.

Test the Phototransistor: To check the phototransistor, place the multimeter probes on pins 3 (collector) and 4 (emitter). In the absence of light, the transistor should have a high resistance (open circuit). When the LED is activated, the resistance should drop, indicating that the transistor is switching.

2. Replace the Optocoupler

If testing reveals that the PC817 is faulty, replacing the optocoupler is often the most straightforward solution. Make sure to use a new component of the same type and rating. Be cautious about static discharge, as it can damage sensitive components.

3. Improper LED Biasing

To fix issues related to improper biasing, check the resistors in series with the LED. The PC817 LED typically requires a current-limiting resistor to prevent excessive current that could damage the LED. Calculate the appropriate resistance value based on the supply voltage and the LED’s forward voltage rating (usually around 1.2V) and ensure the resistor is in place.

If the resistor is too high in value, the LED might not receive enough current to activate the phototransistor properly. On the other hand, if the resistor is too low, the LED might be overloaded and fail. Always use the recommended resistor values from the datasheet.

4. Using Proper Load Impedance

When dealing with weak output signals, it’s crucial to check the impedance of the load connected to the PC817. If the load is too high, the phototransistor will not be able to drive it properly. In such cases, consider adding a buffer or an amplifier stage between the PC817 and the load to ensure proper signal transfer.

5. Eliminate Noise and Interference

To reduce noise and signal interference issues, you can take several steps:

Use Decoupling capacitor s: Place capacitors near the power supply pins of the PC817 to reduce high-frequency noise. A typical value for decoupling capacitors ranges from 0.1µF to 10µF.

Shielding: In noisy environments, consider shielding the circuit to prevent electromagnetic interference (EMI) from affecting the PC817’s performance.

Improve Layout: A well-designed circuit board layout with proper trace routing can help minimize noise. Ensure that the high-current and high-frequency traces are kept away from the optocoupler’s input and output traces.

6. Prevent Overload and Overheating

Ensure that the PC817 is operating within its specified current and voltage ratings. Overloading the component can lead to failure, while excessive heat can damage the internal LED or phototransistor. Use heat sinks or ensure proper ventilation in high-power applications to prevent thermal damage.

7. Proper Mounting and Soldering

If the PC817 is not mounted or soldered correctly, it may lead to intermittent faults or complete failure. Ensure the component is securely mounted on the PCB, and use proper soldering techniques. Excessive heat during soldering can damage the internal components, so be careful not to overheat the pins.

In conclusion, the PC817 optocoupler is a reliable component widely used in signal isolation applications. However, like all electronic components, it can experience various issues over time. By following the troubleshooting methods outlined above, you can quickly identify and resolve common problems, ensuring that your circuits remain functional and efficient. Proper circuit design, correct biasing, and routine testing are key to preventing failure and extending the lifespan of the PC817 optocoupler.

If you’re looking for models of commonly used electronic components or more information about () datasheets, compile all your procurement and CAD information in one place.