THVD1400DR Common troubleshooting and solutions

In this article, we explore the most common issues users may encounter with the THVD1400DR and offer practical solutions to troubleshoot and resolve them. Whether you’re a beginner or an experienced user, this guide will ensure smooth operations of your THVD1400DR device.

THVD1400DR, troubleshooting, solutions, common issues, device problems, Power Management , voltage issues, THVD1400DR troubleshooting guide, THVD1400DR problems, electronics troubleshooting, power devices

Introduction to the THVD1400DR and Its Importance

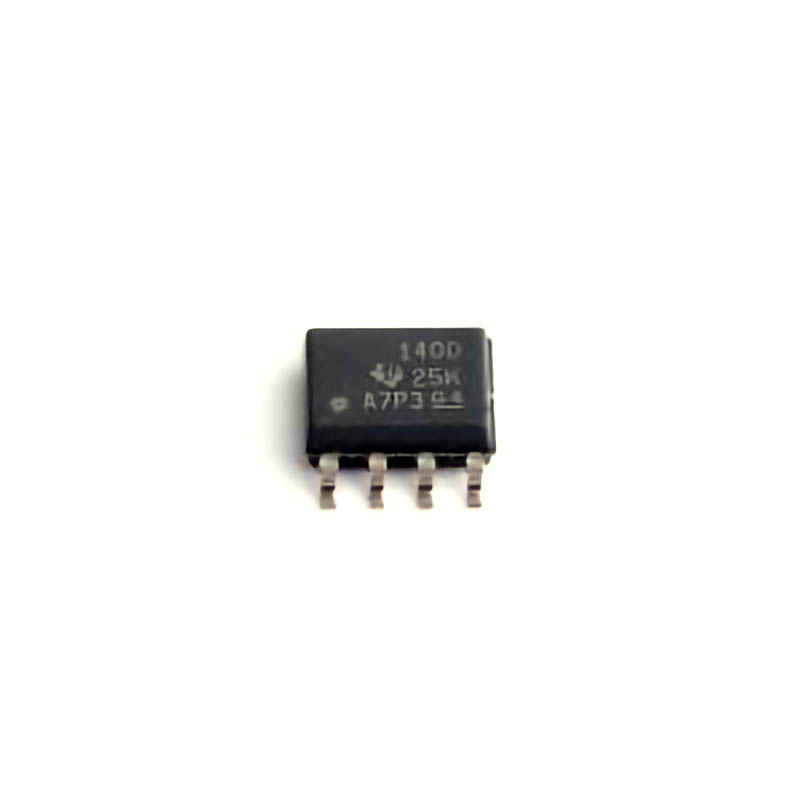

The Texas Instruments THVD1400DR is a versatile and highly efficient integrated circuit (IC) that is often used in a wide range of applications, from industrial controls to consumer electronics. Its primary role is to serve as a high-speed, robust transceiver for differential voltage signaling systems. Its primary features include low-power operation, high voltage tolerance, and robust performance across a variety of environmental conditions.

However, like any piece of technology, the THVD1400DR may experience occasional issues. These can arise from improper configurations, Electrical noise, or even user error. Fortunately, many of these issues can be resolved through basic troubleshooting and preventative measures. In this article, we’ll walk you through common problems and their solutions to help you get your THVD1400DR back to optimal performance.

Common Troubleshooting Issues and Solutions

Power Issues and Device Not Turning On

One of the most common issues users face with the THVD1400DR is a failure to power up or malfunctioning due to power-related problems. If the device does not turn on, the following steps should be taken:

Check Power Supply: The THVD1400DR operates on a specific voltage level, typically between 3.0V and 3.6V. Ensure that your power supply is providing the required voltage and that there are no fluctuations that could affect performance.

Inspect Power Pins: Double-check the power supply pins (VCC and GND). Ensure they are correctly connected and there are no loose connections. A misconnection here is a frequent cause of power failure.

Verify Grounding: Improper grounding can lead to erratic behavior, including failure to power on. Ensure the GND pin is correctly grounded, and there is no floating voltage that could interfere with the device’s operation.

Check for Shorts or Overcurrent: If there is a short circuit or an overcurrent situation, the device might be drawing excessive power, causing it to malfunction or shut down. Use a multimeter to verify the power consumption and check for any faults in the circuitry.

Signal Integrity Issues (Distorted Signals)

When using the THVD1400DR for high-speed data transmission, signal integrity can sometimes degrade, causing data errors or corrupted transmissions. This can be caused by several factors:

Insufficient Termination: High-speed transceivers, like the THVD1400DR, require proper termination to ensure signal clarity. Insufficient termination at the receiving end can cause reflections and signal degradation. Ensure that the impedance is correctly matched between the transmitter and receiver.

Noise and Interference: Electromagnetic interference ( EMI ) from nearby devices or poorly shielded cables can degrade signal quality. Check for sources of EMI in your environment and ensure the THVD1400DR’s cables are properly shielded.

PCB Layout Issues: Poor PCB layout can result in issues like ground bounce or improper routing of traces. Ensure the PCB layout adheres to best practices for high-speed signal integrity. Specifically, keep traces as short as possible, and use proper ground planes and decoupling capacitor s.

Communication Failures or Loss of Data

Intermittent communication failures can occur due to several reasons, including incorrect configuration settings or poor signal quality. Here are the key areas to check:

Check Baud Rate Configuration: Ensure that the baud rate is correctly configured on both transmitting and receiving ends. A mismatch in baud rates between devices is a common cause of communication failure.

Verify Mode of Operation: The THVD1400DR can operate in various modes such as half-duplex or full-duplex. Ensure that both devices connected via the THVD1400DR are using the same mode of communication.

Check for Timing Mismatches: Timing errors can cause communication issues. Verify the timing parameters, including clock speed and signal synchronization. Improper timing can lead to data loss or corruption.

Inspect Data Line Integrity: Ensure that the data lines (TX and RX) are not damaged or improperly connected. A poor connection or broken wire can cause intermittent communication problems.

Overheating and Thermal Management

Another common issue that affects the performance of the THVD1400DR is overheating, which can lead to failure or reduced functionality. Here’s how to address thermal issues:

Check Operating Temperature Range: The THVD1400DR is designed to operate within a specific temperature range. Exceeding this range can lead to thermal shutdown or malfunction. Ensure that the operating environment does not exceed the maximum rated temperature of the device, typically around 125°C.

Use Adequate Heat Dissipation: If the THVD1400DR is mounted on a PCB, ensure there is proper thermal management in place. Use heat sinks, thermal vias, or a well-designed PCB layout that allows heat to dissipate effectively.

Monitor Power Consumption: Overpowering the device can lead to excessive heat generation. Monitor the current draw to ensure that it remains within the safe operating limits. If the current exceeds the recommended values, adjust the system’s power supply or use additional heat dissipation measures.

Electrical Overstress or Damage to Pins

Overstress or electrostatic discharge (ESD) can cause permanent damage to the THVD1400DR’s pins. If the device shows signs of erratic behavior, such as intermittent failures or loss of functionality, follow these steps:

Verify Pin Connections: Check all pin connections to ensure they are correct and there are no physical shorts. A short between pins, especially between power and ground, can lead to severe damage.

Check for ESD Protection: The THVD1400DR should be protected against electrostatic discharge. If you are handling the device, ensure you are using proper anti-static precautions, such as wearing a wrist strap and working on an ESD-safe surface.

Inspect for Pin Damage: If the device has been exposed to a voltage spike or improper connection, pins may become damaged or stressed. Check the physical integrity of the pins and replace the device if necessary.

Intermittent Operation or Random Restarts

If the THVD1400DR is behaving erratically or rebooting unexpectedly, the following factors may be at play:

Power Supply Instability: An unstable or fluctuating power supply can cause the device to reset intermittently. Verify the stability of your power supply and consider using a more reliable source or a regulated power supply.

Faulty Connections: Loose or unreliable connections, especially on the power and ground pins, can cause intermittent behavior. Double-check all connections for tightness and reliability.

Faulty Components in the Circuit: Sometimes, other components in the circuit can cause interference or faults that affect the THVD1400DR. Inspect all connected components for signs of damage, wear, or failure.

Preventative Measures and Best Practices

While troubleshooting can resolve many issues, preventative maintenance is just as important in ensuring the long-term reliability of the THVD1400DR. Here are a few best practices to follow:

Regularly Inspect and Test: Periodic testing of the THVD1400DR’s performance can catch potential issues early. Use tools like oscilloscopes and multimeters to check the voltage levels, signal integrity, and overall performance.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s specifications regarding voltage, temperature range, and wiring configurations. Following these guidelines ensures optimal performance and minimizes the risk of damage.

Use Proper Shielding: Electromagnetic interference is a major source of malfunction in high-speed communication circuits. Make sure to use proper shielding around the device and its connected components to protect against external noise.

By following these troubleshooting tips and best practices, you can ensure that your THVD1400DR operates smoothly and efficiently, minimizing downtime and improving reliability in your projects. Whether dealing with power issues, signal integrity, or communication failures, the right steps can restore your device to full functionality and keep your operations running without interruption.

If you’re looking for models of commonly used electronic components or more information about THVD1400DR datasheets, compile all your procurement and CAD information in one place.

(Partnering with an electronic component supplier) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. (Contact us) for free today