CAT24C512WI-GT3 Common troubleshooting and solutions

Understanding the CAT24C512WI-GT3 and Common Issues

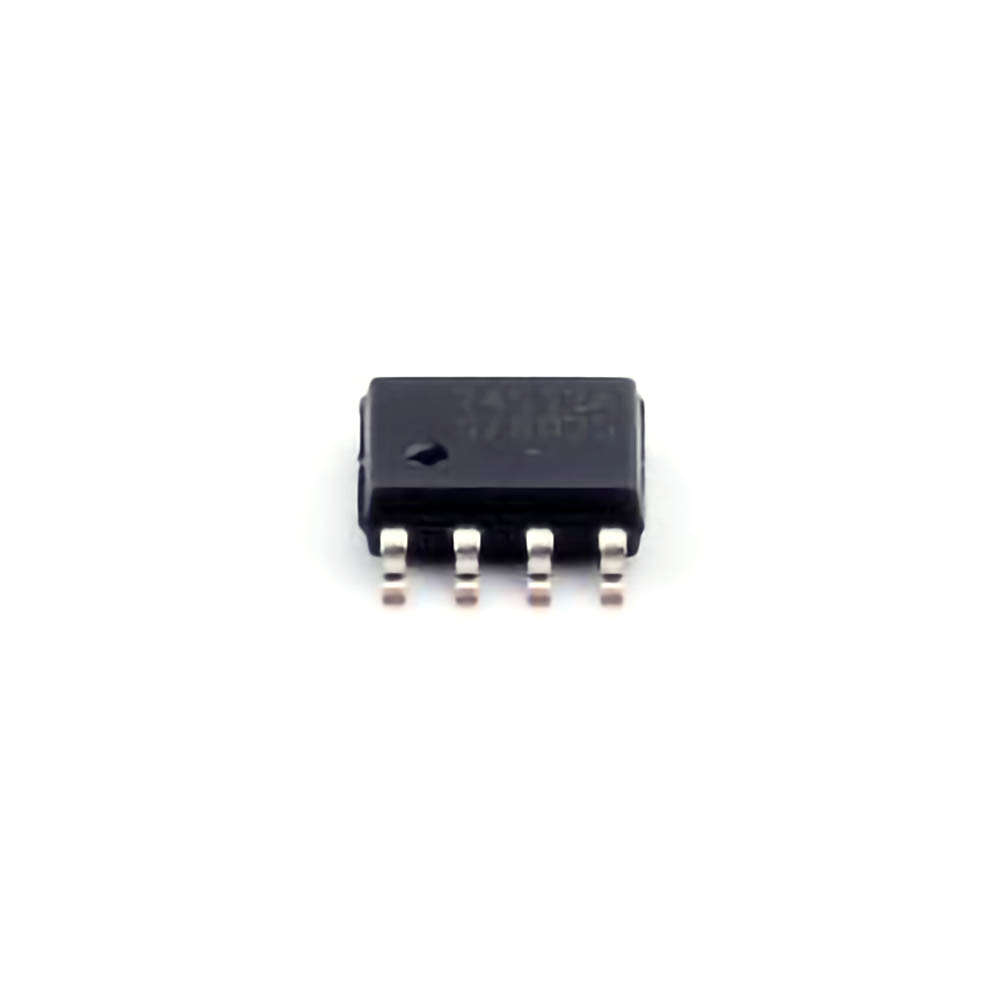

The CAT24C512WI-GT3 is a 512Kb (kilobit) I2C EEPROM ( Electrical ly Erasable Programmable Read-Only Memory ) that has found its way into many electronics applications due to its flexibility, compact size, and low Power consumption. It’s commonly used in embedded systems, memory expansion, and data logging applications. While this component is robust and reliable, it is not impervious to issues that could hinder its functionality. Here’s a look at some common problems and their causes.

1. No Communication with the EEPROM

One of the most frequent issues users experience with the CAT24C512WI-GT3 is a failure in communication with the device. This could be due to multiple factors, and it’s essential to narrow down the cause.

Possible Causes:

Incorrect I2C Address: The CAT24C512WI-GT3 operates with a default I2C address (0xA0 for write operations, 0xA1 for read operations). If the microcontroller or other device you’re communicating with is set to a different address, the EEPROM will not respond.

Wiring Issues: Make sure that the connections between the EEPROM and the microcontroller are secure. A loose or disconnected wire, especially for the SDA (Serial Data) or SCL (Serial Clock ) lines, can prevent communication.

Power Supply Problems: The EEPROM needs a stable power supply (usually 3.3V or 5V depending on the version). Fluctuating voltage or inadequate power can cause malfunction.

Solutions:

Double-check the I2C address in the software to ensure it matches the EEPROM’s default or the user-configured address.

Inspect all wiring, particularly the SDA and SCL lines, for any physical damage or loose connections.

Verify that the EEPROM is receiving the correct voltage. Measure the supply voltage with a multimeter to ensure it's stable.

2. Data Corruption or Unreliable Data Storage

Sometimes, users find that data stored in the EEPROM is either corrupted or unreliable, meaning that previously written data does not persist after power cycling or is inaccurately read back.

Possible Causes:

Insufficient Write Time: After writing data to the EEPROM, the device needs a certain amount of time to store the data. If the microcontroller reads the data too soon before the write cycle is complete, it could result in incorrect or incomplete data.

Improper Write Protection: The CAT24C512WI-GT3 has built-in write protection features that can prevent unwanted writes. However, if these protections are not properly managed, it could prevent successful writes or lead to data corruption.

I2C Clocking Issues: An unstable clock signal or a clock speed that is too high for the EEPROM can also result in data corruption.

Solutions:

Implement a small delay after each write operation to ensure that the EEPROM has sufficient time to complete its write cycle. Typically, a delay of around 5 milliseconds should suffice, but you should refer to the datasheet for the specific time required.

Check the write protection settings. Ensure that the WP pin (Write Protect) is properly configured. If it's not grounded, the device will be in write-protected mode.

Use a more stable clock source or reduce the clock speed if you suspect clock issues. The CAT24C512WI-GT3 supports I2C communication speeds up to 1 MHz, but lower speeds might be more reliable in some setups.

3. No Power on Reset

In some cases, the CAT24C512WI-GT3 may fail to reset properly after power-on, making it appear dead or unresponsive.

Possible Causes:

Power Supply Issues: If the EEPROM’s power supply is not stable, it might fail to reset when power is first applied.

I2C Bus Contention: If multiple devices are connected to the same I2C bus and one of them is not properly initialized, it could cause the whole bus to lock up, preventing communication with the EEPROM.

Poor Reset Circuit Design: The CAT24C512WI-GT3 has an internal reset function that is activated by power-on. However, if the reset circuit is poorly designed or the power-up sequence is not correct, it might prevent the EEPROM from initializing properly.

Solutions:

Ensure the power supply to the EEPROM is within the recommended range and is stable. Use decoupling capacitor s (typically 100nF) near the power pins to smooth out voltage spikes and fluctuations.

If other I2C devices are connected to the same bus, ensure they are properly initialized and not causing bus contention. Use pull-up resistors on the SDA and SCL lines as required to stabilize the communication.

Check the reset circuit. If necessary, add a dedicated reset IC to ensure proper initialization of the EEPROM after power-on.

4. Incorrect Data Addressing

Another issue users may encounter is difficulty writing or reading data from specific addresses within the memory. The CAT24C512WI-GT3 allows random access to its memory, but improper addressing could result in errors.

Possible Causes:

Addressing Errors in Software: When reading or writing data, if the address is not properly aligned or if an incorrect address is used, the operation will fail.

Page Boundaries: The CAT24C512WI-GT3 has internal memory pages (typically 64 bytes each). If data is written across page boundaries without considering these boundaries, it can result in incorrect data being written.

Solutions:

Ensure that the software correctly handles memory addressing. Double-check that the address specified in the software matches the desired memory location.

When writing to the EEPROM, make sure that data is written within the bounds of the current memory page. If you need to cross a page boundary, first write to the end of the current page, then proceed to the next page.

Advanced Troubleshooting and Preventive Maintenance for the CAT24C512WI-GT3

While the issues mentioned in Part 1 cover the more common problems users encounter, there are also advanced troubleshooting techniques and maintenance practices that can prevent issues from occurring in the first place or help you address them when they arise.

1. Monitoring I2C Bus Traffic

If you suspect I2C communication issues that are not immediately apparent, using an I2C bus analyzer or logic analyzer can be invaluable. These tools allow you to monitor the actual traffic between the microcontroller and the EEPROM and can help pinpoint problems such as incorrect addressing, missed clock signals, or unexpected data.

Solutions:

Use an I2C bus analyzer to capture communication between the EEPROM and the microcontroller. Look for any errors such as corrupted addresses, incomplete data frames, or bus contention.

Compare the data packets to the expected format as specified in the CAT24C512WI-GT3 datasheet. This will help you identify if the problem lies in the software or hardware.

2. Firmware and Software Debugging

The software you use to communicate with the EEPROM is as important as the hardware itself. A bug in the code could cause communication failures, memory corruption, or improper device operation.

Solutions:

Review the firmware carefully for any logic errors. Ensure that write and read operations are correctly sequenced, and that you’re respecting the EEPROM's timing requirements.

Use a debugger to step through your code and verify that the correct data is being written to the correct memory locations.

If you're using an I2C library or driver, check for known bugs or issues and ensure it's up-to-date.

3. Environmental Factors and Interference

External factors such as electromagnetic interference ( EMI ) or temperature fluctuations can affect the performance of I2C devices, including the CAT24C512WI-GT3. High levels of noise on the SDA or SCL lines can corrupt data and lead to unreliable performance.

Solutions:

Use proper shielding and layout techniques to minimize EMI. Ensure that the I2C lines are kept short and away from high-power lines or sources of interference.

Ensure the operating temperature range of the EEPROM is suitable for your environment. The CAT24C512WI-GT3 operates within a specific temperature range (typically -40°C to +85°C). If your application operates outside this range, it could affect reliability.

4. Proper Testing and Calibration

Regular testing and calibration of your circuit can catch potential issues early before they affect system performance.

Solutions:

Periodically test the EEPROM in your system using diagnostic software or by writing known patterns of data to it and reading them back.

Perform in-circuit testing (ICT) on the I2C lines to ensure that the communication is stable and reliable.

5. Use of Capacitors for Stability

One of the easiest and most effective ways to enhance the reliability of the CAT24C512WI-GT3 is to add decoupling capacitors to the power supply lines. These capacitors help to smooth out voltage fluctuations and prevent glitches that could affect memory operations.

Solutions:

Place a 0.1µF ceramic capacitor and a 10µF electrolytic capacitor close to the power pins of the EEPROM for optimal performance.

Conclusion

The CAT24C512WI-GT3 is a highly reliable and versatile EEPROM, but like any component, it can experience issues that may impact your project or design. By understanding the common problems and implementing the troubleshooting steps outlined in this article, you can ensure that the EEPROM performs optimally and reliably. With careful attention to wiring, addressing, power supply, and timing, you can minimize the occurrence of errors and keep your system running smoothly.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.