DS18B20U Common troubleshooting and solutions

Sure! Here’s a 2000-word soft article on the theme “ DS18B20 U Common Troubleshooting and Solutions,” divided into two parts of 1000 words each:

This article provides a comprehensive guide to troubleshooting and solving common issues faced when using the DS18B20 U temperature Sensor . From wiring mistakes to software errors, we cover all potential problems and offer easy-to-understand solutions for DIY electronics enthusiasts and engineers.

DS18B20U , temperature sensor, troubleshooting, common issues, solutions, DIY electronics, temperature measurement, Arduino, Sensors , hardware problems, software fixes.

Understanding the DS18B20U Temperature Sensor

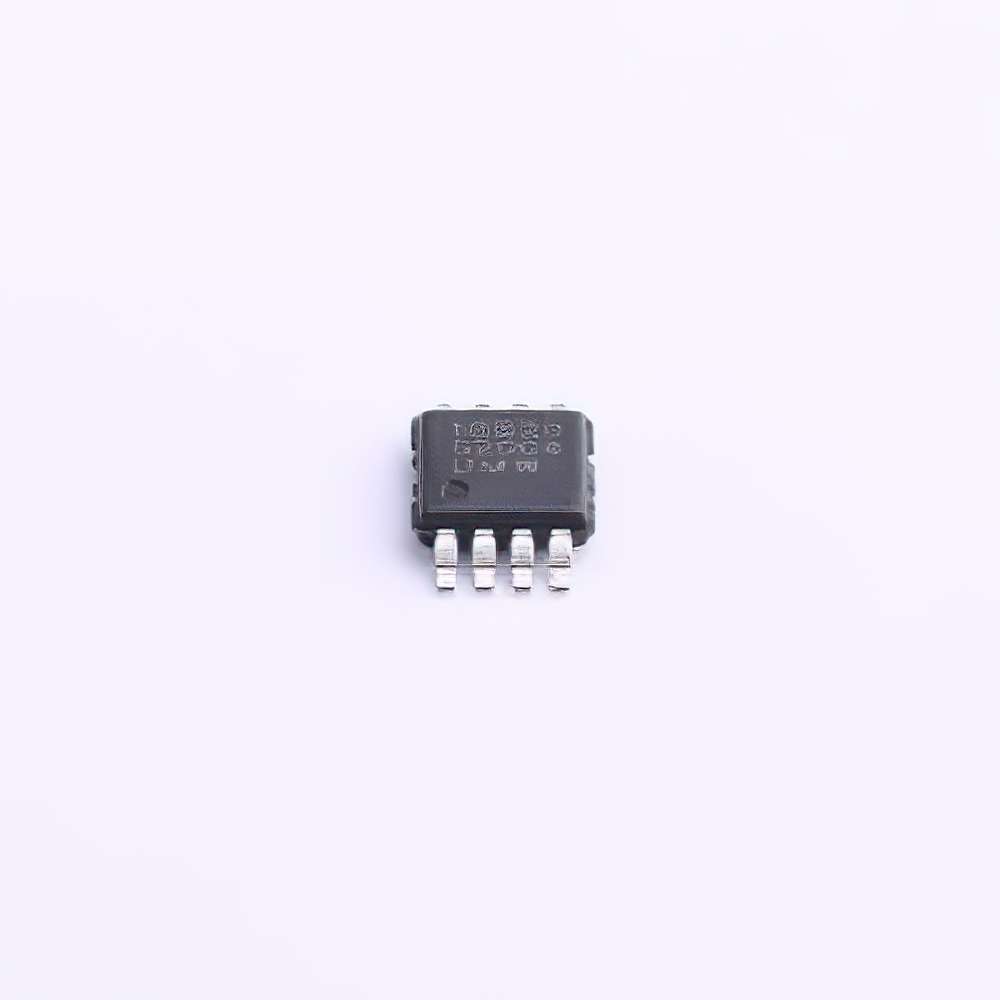

The UMW DS18B20U is a popular digital temperature sensor used in a variety of DIY electronics projects, home automation systems, and industrial applications. Its 1-Wire Communication protocol makes it easy to interface with microcontrollers like Arduino, Raspberry Pi, and others. Despite its popularity and ease of use, there are certain issues that users often encounter while working with this sensor. In this part, we’ll explore common problems associated with the DS18B20U and the steps you can take to resolve them.

1. Wiring Issues

One of the most frequent causes of malfunction with the DS18B20U sensor is improper wiring. Incorrect connections can prevent the sensor from transmitting data correctly, leading to inaccurate or no readings at all.

Solution: Correcting Wiring Connections

The DS18B20U sensor typically has three pins:

VCC ( Power ): Connect this to the 3.3V or 5V pin of your microcontroller (depending on your setup).

GND (Ground): Connect this to the ground of your microcontroller.

DQ (Data): This pin is used for communication between the sensor and the microcontroller.

For the 1-Wire communication to work effectively, the DQ pin also needs to be connected to a pull-up resistor (typically 4.7kΩ) to maintain the proper voltage levels. Make sure the connections are tight, and the wires are not damaged.

If you are using multiple sensors on the same bus, ensure that all DQ lines are properly connected to their respective VCC and GND pins, and that the pull-up resistor is placed in the correct position.

2. No Temperature Readings (Sensor Not Detected)

Another common issue is when the DS18B20U sensor is not detected by the microcontroller. This can happen due to issues with the wiring, a faulty sensor, or software problems.

Solution: Verifying the Sensor Detection

First, check the wiring again to ensure that the connections are stable and correct. If you are using an Arduino or Raspberry Pi, you can use diagnostic software to scan for connected sensors.

On Arduino: Use the “OneWire” and “DallasTemperature” libraries. Upload a simple sketch to scan for the DS18B20U sensor. If the sensor is not detected, you may get a “No sensor found” message.

On Raspberry Pi: Open the terminal and run cat /sys/bus/w1/devices/w1_bus_master1/w1_master_slave. If the sensor is connected properly, the ID of the DS18B20U should appear.

If the sensor still doesn’t show up after these checks, it could be a faulty unit. In that case, try using another sensor.

3. Incorrect Temperature Readings

If the sensor is detected but the readings are incorrect (e.g., displaying a temperature of 85°C or -55°C), this typically indicates a software or hardware issue.

Solution: Checking for Software Bugs and Sensor Calibration

Software Check: Ensure that your code is correctly written to request and read the temperature data. Libraries like “DallasTemperature” are designed to make this process easier and help ensure the sensor is properly initialized.

Calibration: The DS18B20U sensor has an accuracy range of ±0.5°C. If you’re getting abnormal readings, it could be that the sensor requires calibration. Consider adding a small delay between reading temperatures in your code to ensure accurate data retrieval.

Addressing Electrical Noise: Electrical interference can sometimes cause the DS18B20U to give incorrect readings. Ensure that your sensor wiring is not exposed to strong electromagnetic fields, and keep the cables as short as possible to minimize noise.

4. Inadequate Power Supply

The DS18B20U sensor requires a stable power supply to function properly. If the voltage supplied is too low or fluctuates, the sensor might not work correctly.

Solution: Ensuring Proper Voltage and Current Supply

Check that the VCC pin is correctly connected to a 3.3V or 5V source, depending on your microcontroller’s operating voltage. Some sensors may work better with 5V if you are using long cables or other components in your circuit.

In addition, consider adding a capacitor (e.g., 100nF) between the VCC and GND pins to filter out any voltage spikes or fluctuations.

5. Multiple Sensors on a Single Bus

The DS18B20U uses a 1-Wire bus to communicate, which means multiple sensors can be connected to the same data line. However, managing multiple sensors can sometimes cause problems if the wiring is not done correctly.

Solution: Managing Multiple Sensors

If you plan to use multiple DS18B20U sensors on a single 1-Wire bus, make sure each sensor has a unique address. When reading data, the microcontroller should be able to identify each sensor’s address and retrieve individual readings.

You can use the “OneWire” library in Arduino or similar libraries in other environments to detect and manage multiple sensors on the same bus. Also, ensure that all sensors share the same pull-up resistor, and use appropriate data transmission Timing in your code.

Advanced Troubleshooting Techniques and Solutions

Now that we’ve covered some basic issues and solutions, let’s explore some advanced troubleshooting tips and solutions for the DS18B20U temperature sensor. These methods are for more complex problems that might require a deeper dive into hardware or software settings.

6. Data Corruption or Inconsistent Readings

Sometimes, even with correct wiring and setup, the DS18B20U sensor may provide inconsistent temperature readings. This is often caused by timing issues, electrical interference, or problems in the software logic.

Solution: Synchronizing Data Retrieval and Software Timing

Make sure that your code waits for the sensor to finish converting the temperature before trying to read the value. The DS18B20U requires some time to convert the temperature into a digital format, and attempting to read it too early can result in erroneous values.

In Arduino, use the waitForConversion() function provided by the DallasTemperature library to ensure that the sensor has completed its temperature conversion.

In Raspberry Pi, you can implement a delay or check the conversion status via the cat command to ensure that the sensor is ready to deliver a reading.

Additionally, check your microcontroller’s clock settings. A slow clock might result in timing mismatches between the sensor and your program, causing data corruption.

7. Overheating or Physical Damage

If the DS18B20U sensor is exposed to excessive heat or harsh conditions, it may stop functioning correctly or give inaccurate readings.

Solution: Proper Environmental Conditions

Ensure that the sensor is operating within its specified temperature range of -55°C to 125°C. If you’re using the sensor in an environment with high humidity or exposure to chemicals, make sure it’s adequately protected, possibly by using a waterproof version of the sensor.

If the sensor has been physically damaged, such as from overheating, it’s likely no longer functional, and replacing it would be the best course of action.

8. Faulty or Incompatible Libraries

Software libraries are crucial in interfacing with sensors, and if the libraries are not compatible with your hardware or not configured correctly, it can cause problems like failing to read the temperature data or misinterpreting the sensor’s output.

Solution: Updating and Testing Libraries

Check that you are using the latest version of the libraries for your platform (e.g., DallasTemperature for Arduino or w1-therm for Raspberry Pi). Sometimes, a software update may resolve known bugs or compatibility issues.

Ensure that you are following the correct API calls in your code. Libraries typically require you to initialize the sensor before reading data, so make sure that the initialization steps are correct.

9. Addressing Communication Delays

In applications where real-time data acquisition is necessary, delays in communication between the sensor and microcontroller can affect system performance.

Solution: Reducing Communication Delays

To reduce delays, you can optimize your code to handle multiple sensors more efficiently, use interrupt-driven reads instead of polling, and manage the 1-Wire bus more effectively. For larger projects, consider using hardware interfaces like SPI or I2C, as they provide faster communication rates than 1-Wire.

10. Temperature Conversion Accuracy

While the DS18B20U is generally quite accurate (±0.5°C), users sometimes experience discrepancies when reading temperature data. In some cases, the sensor’s reading may not match the actual temperature.

Solution: Compensating for Errors

If the sensor readings consistently deviate by a specific amount, consider applying a software offset to correct the temperature readings. This can be done easily in your code by subtracting or adding the necessary value.

Alternatively, use an external calibrated thermometer to cross-check the readings and verify the accuracy of the sensor over time. Some advanced users implement algorithms to smooth out readings and improve long-term accuracy.

In conclusion, while the DS18B20U sensor is a highly reliable and easy-to-use device for temperature measurement, it can still present challenges if not properly set up or configured. By following the troubleshooting tips and solutions outlined above, you can ensure that your DS18B20U sensor performs optimally and delivers accurate temperature data for your project.

If you’re looking for models of commonly used electronic components or more information about DS18B20U datasheets, compile all your procurement and CAD information in one place.

( Partnering with an electronic component supplier) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. (Contact us) for free today.