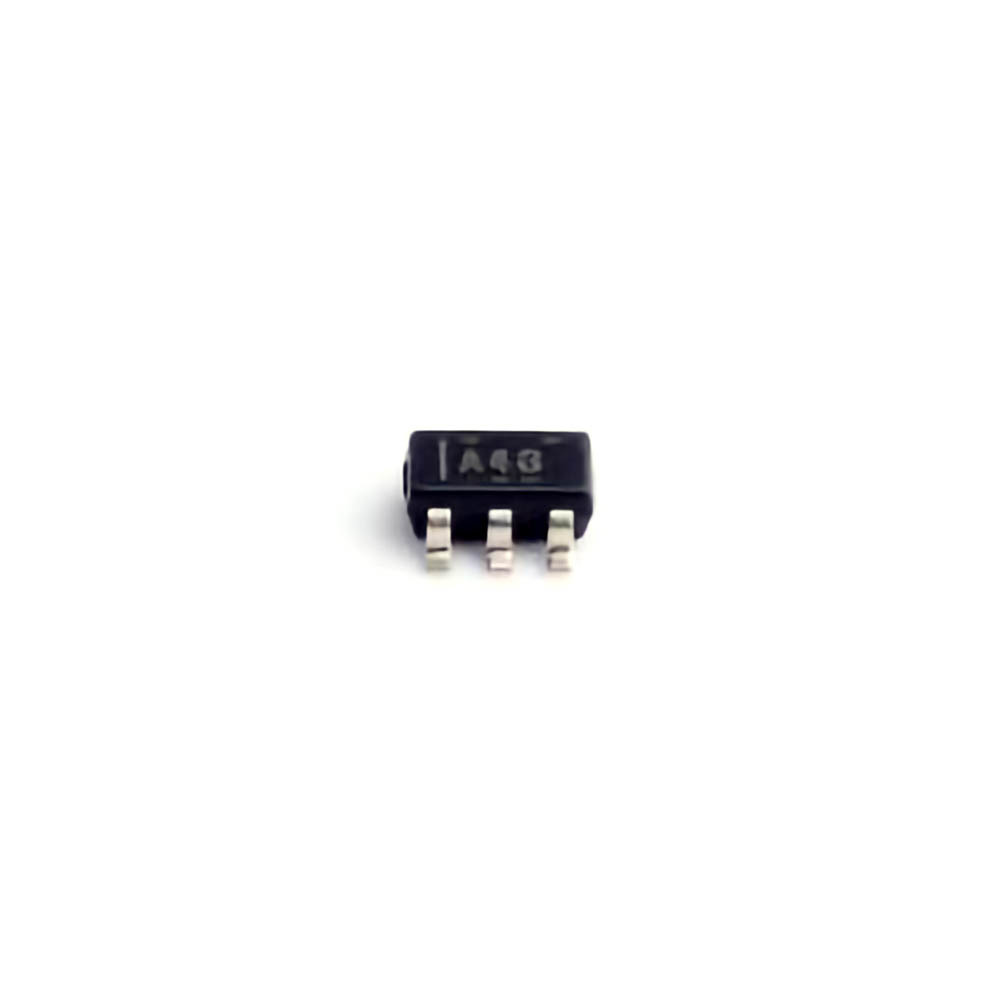

Comprehensive Analysis and Fixes for Drift Problems in OPA348AIDBVR Operational Amplifier

The OPA348AIDBVR operational amplifier is widely recognized for its high precision, low offset voltage, and low Power consumption, making it ideal for applications in industrial, automotive, and consumer electronics. However, like many precision components, the OPA348AIDBVR may experience drift over time, leading to performance degradation. This article offers a detailed analysis of drift problems in the OPA348AIDBVR, outlines the potential causes, and provides practical solutions for fixing these issues to ensure long-term reliability and accuracy.

OPA348AIDBVR, operational amplifier, drift issues, precision amplifier, offset voltage, power consumption, temperature coefficient, circuit stability, fixing drift problems, reliability in op-amps

Understanding Drift Issues in OPA348AIDBVR Operational Amplifiers

Introduction to OPA348AIDBVR and Its Features

The OPA348AIDBVR is a low-power, low-offset voltage operational amplifier designed for a wide range of precision applications. With an input offset voltage as low as 25 µV (max), the OPA348 series is optimized for high-accuracy signal conditioning, filtering, and amplification tasks in systems where stability and precision are critical. Its primary features include low quiescent current, wide bandwidth, and low total harmonic distortion, making it an excellent choice for portable, battery-powered devices.

Despite these advantages, the OPA348AIDBVR, like all operational amplifiers, is not immune to drift. Understanding what causes drift in these components is key to maintaining their accuracy and reliability in demanding applications.

What Is Drift and Why Does It Matter?

Drift in operational amplifiers refers to the gradual and often unpredictable change in key parameters such as offset voltage, bias current, or gain over time or under varying environmental conditions. In the case of the OPA348AIDBVR, the primary concern is typically the drift of the input offset voltage.

Offset voltage drift occurs when the voltage difference between the inverting and non-inverting inputs of the amplifier changes over time. This shift can lead to errors in signal processing, particularly in high-precision applications like instrumentation, Sensor interface s, and medical equipment, where even minor inaccuracies can result in significant performance degradation.

The main contributing factors to drift in the OPA348AIDBVR are temperature changes, aging effects, and bias current variations. These factors are discussed in detail in the following sections.

Factors Contributing to Drift in OPA348AIDBVR

Temperature Sensitivity:

Temperature fluctuations have a profound impact on the performance of operational amplifiers, including the OPA348AIDBVR. As temperature increases, the input offset voltage tends to increase as well, a phenomenon known as the temperature coefficient of offset voltage. In the OPA348AIDBVR, this drift is typically specified as 0.3 µV/°C (typical). In environments where temperatures vary widely, this drift can lead to significant inaccuracies over time.

Aging and Environmental Stress:

Over time, internal components such as transistor s and resistors undergo slight changes due to environmental factors like humidity, pressure, and exposure to electrical stress. These aging effects can cause shifts in the amplifier's performance, particularly in offset voltage and bias currents. The OPA348AIDBVR's design, while optimized for low drift, still faces the inevitable degradation of its materials over long periods.

Bias Current and Offset Voltage Drift:

The input bias current (the DC current required by the inputs of the op-amp to properly operate) also plays a crucial role in the drift behavior of the OPA348AIDBVR. Bias current-related offset voltage drift occurs when variations in the bias current cause changes in the internal circuitry, leading to a shift in the output signal. This phenomenon is especially noticeable in high-impedance circuits.

Power Supply Fluctuations:

Variations in the power supply can contribute to drift, especially in circuits where the OPA348AIDBVR is operating at or near its limits. Ripple from power supplies, fluctuations in voltage, or noise can introduce instability in the amplifier’s performance, further contributing to drift.

Identifying Drift Problems in OPA348AIDBVR

Before addressing the drift problem, it’s essential to identify whether drift is indeed occurring and to what extent it is affecting the performance of the amplifier. There are several ways to detect drift issues:

Precision Measurement Tools:

High-precision voltmeters or digital multimeters (DMMs) can be used to measure any gradual changes in offset voltage over time. By measuring the output of the operational amplifier under controlled conditions, engineers can track any drift and determine whether it is within acceptable limits for the application.

Monitoring Temperature and Environment:

Using thermocouples or temperature Sensors , engineers can correlate drift with temperature changes in the environment. This can help identify if the drift is primarily caused by temperature sensitivity, which is often a key contributor to offset voltage drift.

Simulation and Modeling:

Computer-aided design (CAD) tools and simulation software can help model the behavior of the OPA348AIDBVR in a circuit, allowing engineers to predict and identify areas where drift could occur. Simulation tools can also help optimize circuit designs to minimize drift under various conditions.

Practical Solutions for Fixing Drift Problems in OPA348AIDBVR

1. Temperature Compensation Techniques

One of the most effective ways to mitigate temperature-induced drift in the OPA348AIDBVR is by implementing temperature compensation techniques. Here are some strategies to consider:

Use of Temperature Sensors:

Integrating a temperature sensor with the op-amp circuit can allow for real-time monitoring and compensation. The output from the sensor can be used to dynamically adjust the reference voltage or apply corrective factors to the operational amplifier’s output.

Thermal Coupling:

By coupling the operational amplifier to a temperature-stable reference, engineers can reduce the impact of temperature variations on the amplifier’s performance. Using resistors and other components with low temperature coefficients can further improve stability.

Active Compensation Circuits:

In more advanced designs, active compensation circuits can be built around the OPA348AIDBVR to reduce the temperature dependence of offset voltage. These circuits usually involve the use of additional op-amps, resistors, and sometimes thermistors to counteract the drift caused by temperature fluctuations.

2. Aging Mitigation Strategies

Aging effects are inevitable, but there are ways to reduce their impact and extend the reliable operating life of the OPA348AIDBVR:

Circuit Stress Minimization:

To reduce the stress on the internal components, engineers should avoid excessive voltage or current that could accelerate aging. Ensuring that the OPA348AIDBVR operates within its specified limits helps prolong its life and minimize drift caused by aging.

Use of Higher-Quality Components:

While the OPA348AIDBVR is already designed for low drift, using high-quality external components such as precision resistors and low-noise capacitor s in the circuit can help maintain long-term stability.

3. Bias Current Compensation

Bias current-related drift can be particularly problematic in high-impedance applications, so engineers should consider these solutions:

External Compensation Networks:

Adding external resistive networks can help balance the input bias current, reducing its impact on the op-amp’s performance. In high-impedance applications, this is a common practice to ensure that bias current does not cause significant offset voltage.

Use of Low-Bias Current Op-Amps:

In situations where bias current is a significant contributor to drift, switching to an operational amplifier with even lower bias currents can help. Although the OPA348AIDBVR is already low-bias, some applications may require even stricter performance specifications.

4. Power Supply Stabilization

Fluctuations in the power supply can cause instability in op-amp performance, so proper power supply design is crucial:

Use of Voltage Regulators :

Ensuring a stable and clean power supply can reduce drift caused by supply variations. Voltage regulators and filtering Capacitors can help minimize noise and fluctuations from the power supply, improving the overall stability of the operational amplifier.

Decoupling Capacitors:

Proper decoupling is critical for maintaining low-noise operation. Adding capacitors near the op-amp’s power pins can help filter out high-frequency noise and smooth out any power supply fluctuations that could contribute to drift.

Conclusion

Drift in operational amplifiers such as the OPA348AIDBVR is a critical issue that can significantly affect the performance of precision applications. By understanding the causes of drift—such as temperature sensitivity, aging effects, bias current variations, and power supply fluctuations—engineers can implement various techniques to mitigate its impact. Through temperature compensation, aging reduction strategies, bias current compensation, and power supply stabilization, drift can be minimized, ensuring the OPA348AIDBVR maintains its high performance over time.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.